Once the car was pepped and ready it was onto the enclosure build. This was a combination of trial and error mixed with some loose calculations and estimations around box size. I had worked out utilising box design software that for my sub, a 0.6 cuft sealed enclosure was going to give me good responsive SQ and enough power. This also suited my limited boot incursion requirements so was ideal. Continue reading “159 Custom Bass Project – Stage 4 Enclosure Build”

159 Custom Bass Project – Stage 3 Sound Proofing

Once the planning was complete and I had the Amp prepared for some serious load, it was over to the car for a complete strip of the boot and sound proofing. The approach taken was to utilise a number of different sound proofing materials once I stripped the car back to the shell. Continue reading “159 Custom Bass Project – Stage 3 Sound Proofing”

Related Images:

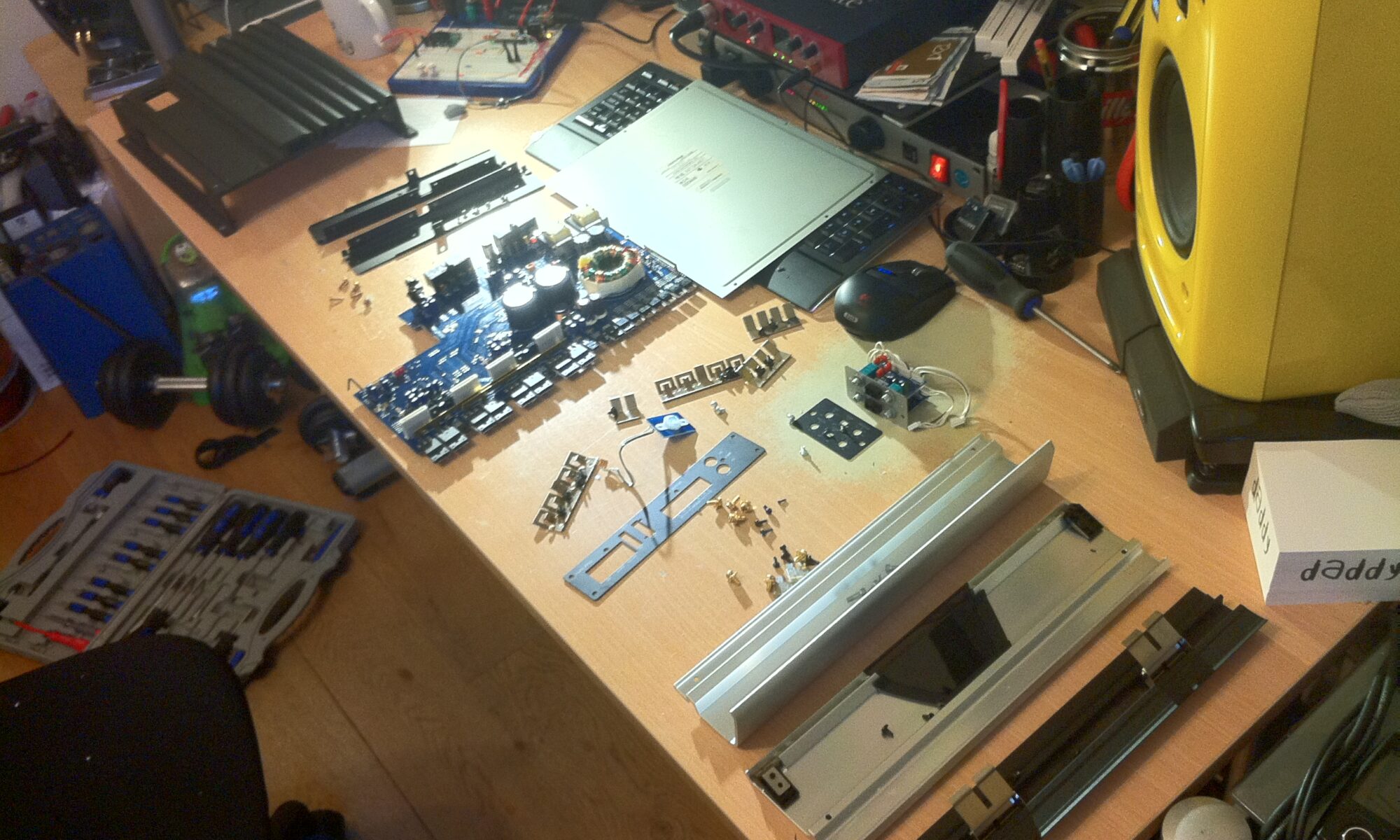

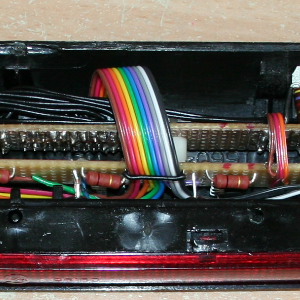

159 Custom Bass Project – Stage 2 Amp Mods

I already had the amplifier and sub from a prior install, and in that install I had discovered a problem with the pairing. The sub is an Infinity Kapa perfect 12 VQ rated at 400w RMS and the amplifier is an Alpine MRV-420 rated at 350W RMS. Driving the sub at high voltage, with line levels in excess of 4v and the gains maxed out means that the amp is producing closer to 450W RMS and the sub, which is well regarded as being able to handle much higher loads than 400W RMS, just laps it up, but had one small issue that needed sorting. It would overheat during extended sessions of Drum and Bass at full power! To sort this issue, I stripped the amp back to bare metal, rebuilt it using high grade CPU heat sink paste and added a temperature controlled cooling system utilising 6 x 40mm fans in a push/pull config. Needless to say, it can run at full power and then some, all day long now ! Continue reading “159 Custom Bass Project – Stage 2 Amp Mods”

Related Images:

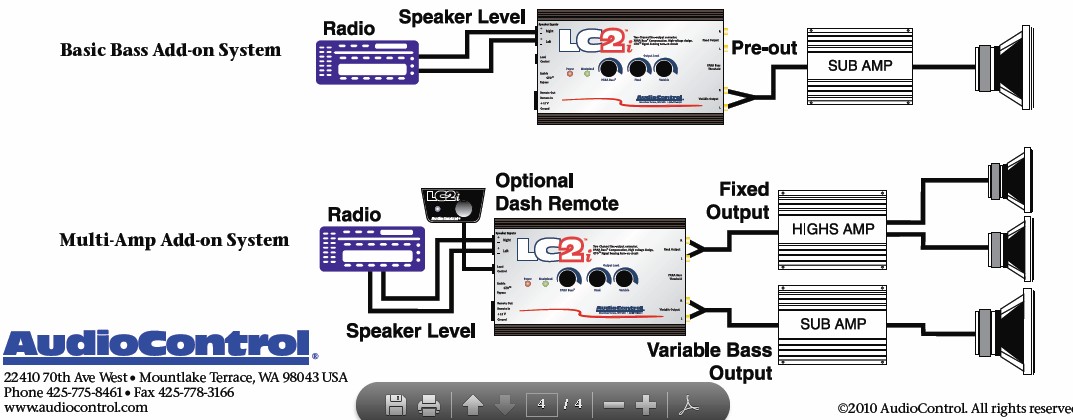

159 Custom Bass Project – Stage 1 Planning

Before I even started this project, I spent quite a lot of time figuring out potential box sizes and planning the acoustics of the project. The overall goal was maximum SQ & Power balance with the least boot space loss possible! No mean feet to achieve. Continue reading “159 Custom Bass Project – Stage 1 Planning”

Related Images:

Alfa 159 TI Full LED Conversion – Exterior Guide

This post covers the exterior lighting modifications made to my 2008 Alfa Romeo 159 TI. If you are interested in the interior LED conversion guide, click here. This modification can be completed as a single project or as a series of smaller projects as the cost of components is still quite high due to some of the LED types in use. If you do choose to split the project I would suggest separating the turn signals / Indicators, Numberplate lights, sidelights and rear clusters into stand alone projects. Continue reading “Alfa 159 TI Full LED Conversion – Exterior Guide”

Related Images:

Alfa 159 TI Full LED Conversion – Interior Guide

This post covers the interior lighting modifications made to my 2008 Alfa Romeo 159 TI.For the exterior LED conversion guide, click here. This modification is worth completing as a single project as the results are a dramatic change in the mood of the interior of the car at night. The original filament bulbs are very yellow so choosing a good LED that puts out a colour range around 6000K changes the feel of the car to a much cooler, relaxed and crisp feel. Continue reading “Alfa 159 TI Full LED Conversion – Interior Guide”

Related Images:

Cylon V5 – Production Ready

This is the final update to the schematics and overall design and concludes the R&D aspects of the project. What I have now is a good mix of design good practice and intelligent thinking that results in a solid architecture for a production run. So far I have just prototyped the design into the car using readily available breadboards, however, the next step is to move to a manufactured circuit board that will give much better longevity and easier assembly. Continue reading “Cylon V5 – Production Ready”