So, many of you who read my previous post on the TEVO Black Widow 3D printer might have thought, oh hes bought another toy. Well, while that is mostly true I had an actual reason for getting one. Continue reading “My First “Thing””

The Cylon

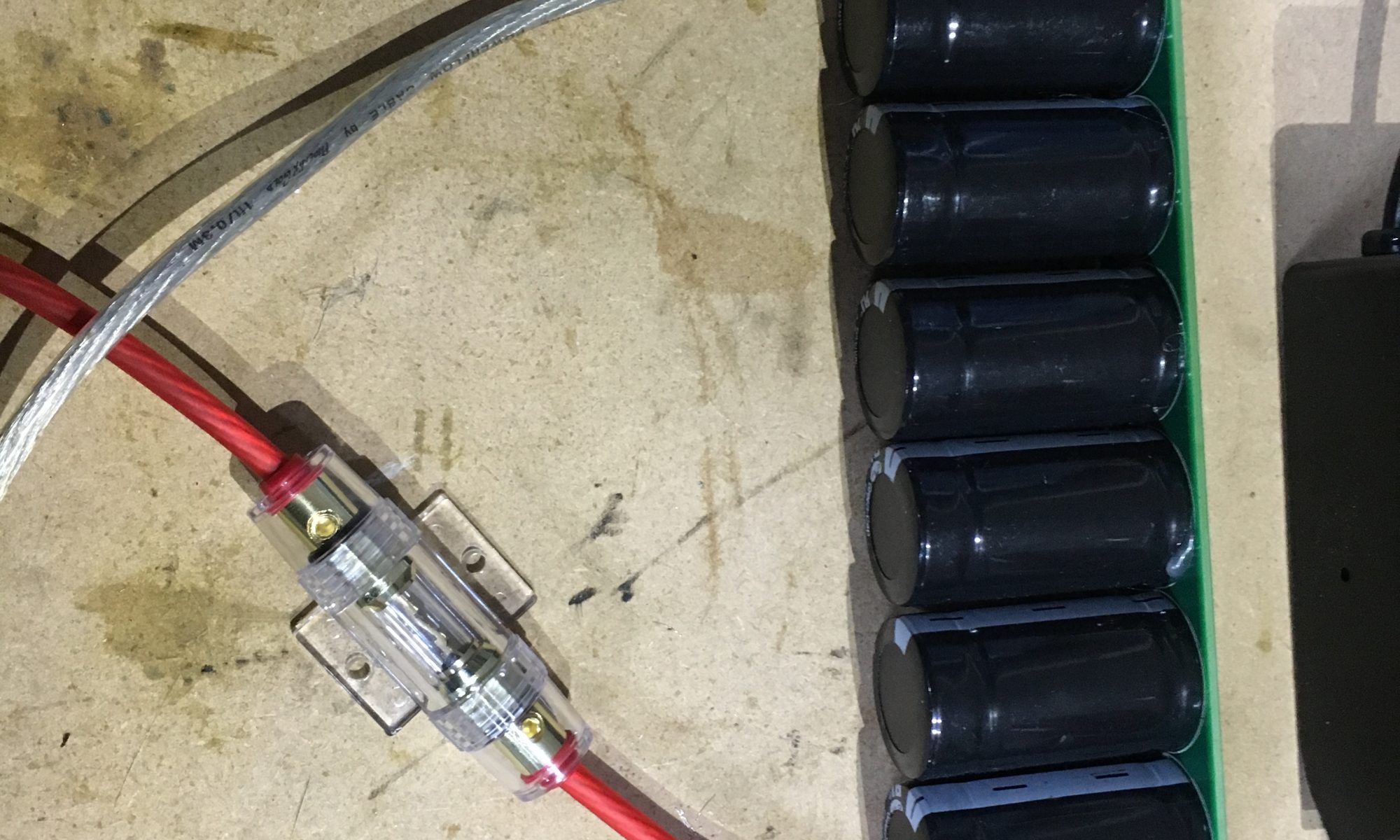

12v Super Capacitor Bank

For a while now I have been looking into alternative power solutions for the Alfa due to its power hungry nature that is not helped by the many auxiliary systems I have added over time. Continue reading “12v Super Capacitor Bank”

Related Images:

Make your own 12V 10s off Relay

Here is a simple scheme for 12V approx 10s OFF Relay. It’s very easy to build. Scheme and part list are shown below. Continue reading “Make your own 12V 10s off Relay”

Related Images:

Bumper Removal

Introduction

What follows is the front bumper removal procedure as described by Alfa Romeo in their in-house dealer level procedure software, eLearn. This is a descriptive and pictorial guide to removing the bumper as used by Alfa Romeo trained technicians – but I am pretty sure use mere mortals can follow it too! Continue reading “Bumper Removal”

Related Images:

Power Supplies

Overview

The Halo units require good, clean regulated power to run or they will burn out. A cars power supply is the exact opposite of this, its dirty, unregulated and a very bad place for electrical items to live! As such, most electronics in a car have additional protective mechanisms to keep then safe. The Halo controllers & rings are no different. Continue reading “Power Supplies”

Related Images:

Installation of the Rings

Overview

Installation of the rings is very easy. Each ring is a near exact size match for the lens so they are easy to place in the right ones. For reference, the rings are: Continue reading “Installation of the Rings”